Atlas Copco enhances plant efficiency through compressor room optimization

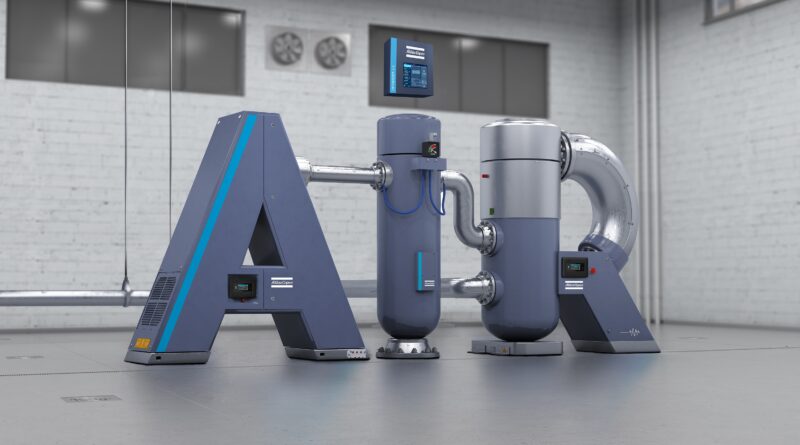

Acutely aware of customers’ need to reduce operational costs for enhanced plant efficiency and business sustainability, Atlas Copco is leveraging its innovative expertise to the development of cutting-edge products and technologies that provide effective plant optimisation solutions.

Compressed air is a crucial utility in industrial processes, but it is also one of the highest consumers of energy. Subsequently, any savings made along the compressed air network will yield economic and financial benefits. Recognising that every plant, application, and customer requirement is unique, Atlas Copco’s products, including machines, software, and technology, are engineered for compatibility and integration, ensuring an optimum solution for every scenario.

“Our Industry 4.0-ready Central Controllers, including Equalizer 4.0, Equalizer 4.0 PRO, and Optimizer 4.0, are designed to enhance compressed air systems by meeting air demand while minimizing costs and reducing CO₂ emissions,” says Louwrens le Roux, Advance Service Sales Engineer at Atlas Copco Compressor Technique.

These Central Controllers enhance process stability and lower a compressor’s energy consumption by an average of 7% for each bar of pressure reduced. Their versatility extends to interfacing with non-Atlas Copco machines, providing maximum flexibility in optimizing any plant, regardless of the compressor brand. “Our goal is to deliver the best possible solution for every customer,” says Le Roux.

As their names suggest, the Equalizer 4.0 and Equalizer 4.0 PRO balance running hours across selected fixed speed and variable speed drive (VSD) compressors, ensuring even and efficient machine usage and reducing idle times, under all conditions, based on predefined priorities. Ideal for plants operating multiple compressors, these units prevent operators from overrunning one machine while the others stand idle. By ensuring equal wear, maintenance can be carried out on multiple machines during a single technician visit, minimising both downtime and maintenance costs, upscaling reliability and extending compressor lifetime. Equalizer 4.0 is recommended for between 2 to 6 connected compressors and the Equalizer 4.0 PRO is capped at 8 connected machines within a common air net.

The Optimizer 4.0 optimizes all connected compressor’s use under all conditions, reducing energy, regulating VSD at best and avoiding energy waste for turbo compressors, by software algorithms optimizing each compressor’s control Philosophy, regulates VSD and minimises energy use and CO₂ emissions. However, Le Roux points out that an Optimizer may not be suitable for every compressed air system and explains: “For instance, a spike lasting a few minutes or even just a few seconds, can overthrow the Optimizer’s control Philosophy. So, before proposing an Optimizer for a customer, we need to gather critical data such as flow consumption and capacity usage, and we need to closely monitor the system. This is where our Equalizer 4.0 and Equalizer 4.0 PRO come into play.” He adds that they can create simulations and even send data to their factory in Belgium for a detailed assessment, enabling them to devise the most effective solution.

With the capability to manage up to 60 connected machines (30 compressors and 30 Ancillary equipment such as air dryers, PSA units, energy recovery, etc.) and control up to 3 separate air nets, the ISO 50001 compliant Optimizer 4.0 is suitable for larger applications. Le Roux describes the Optimizer 4.0 as the ‘grandfather’ of Central Controllers. Instead of one machine operating for 9 000 hours, it distributes the workload among 3 machines, each thus running for only 3 000 hours. This approach enhances machine reliability, availability, and lifecycle while reducing maintenance needs. Le Roux explains that the Central Controllers can optimise down-the-line equipment as long as the ancillaries are equipped with functionalities.

The Central Controllers can be seamlessly integrated into the customer’s SCADA system, allowing the operator to view the controller remotely from the control room via communication protocols. This communication interface provides operators with valuable insights into each connected compressor’s temperature, pressure, and flow. The technology for this smart remote monitoring is already integrated into the Optimizer 4.0 and Equalizer 4.0 PRO. A gateway must be added to Equalizer 4.0 to enable remote monitoring.

The visibility of the compressor’s functionality is important. Checking the status of each connected compressor on a clear digital touchscreen display versus paging through a lengthy document to find the necessary information, allows for efficient control and rapid response should an issue arise. Visibility thus directly correlates with proactive or preventative maintenance that can mitigate costly failures, downtime and subsequent production losses.

After addressing compressor control, remote monitoring, and energy recovery in compressor room optimization, Le Roux highlights another key aspect, namely the potential of air compressors as sources of energy. He notes that 94% of the electrical energy used to generate compressed air is converted into heat. Instead of letting this heat dissipate into the atmosphere, Atlas Copco has developed an energy recovery system, ER 90-900 for oil-free air compressors and the ER S1-S5 for oil-injected machines, to capture and repurpose it. This recovered hot water can be utilized for various applications, including sanitary purposes, space heating, as a pre-feed for boilers or in processes requiring 70-90°C hot water. The enhancement of customers’ central heating systems conserves resources, reduces the consumption of natural gas and heating oil, and lowers CO₂ emissions.

Complementing these energy recovery units is Atlas Copco’s Thermo Kit that comprises a buffer vessel connected to the central heating system that stores the water heated by the energy recovery system. Available in two sizes, a 400l and 800l vessel for 11-45 kW and 45-90 kW compressors respectively, the Thermo Kit is compatible with free-standing S1-S5 energy recovery systems and can be retrofitted or supplied fully integrated from the factory.