Atlas Copco’s Three-Tiered Compressed Air Solutions: A Testament to Efficiency

Atlas Copco has led the global market in compressed air technology for over 150 years, garnering unparalleled experience and know-how in the design, engineering and development of one of the most expansive air compressor portfolios available in the market.

“In addition to our globally renowned premium products, we also provide a range of high-quality entry-level options designed to cater to a more budget-conscious segments of the market,” says Dean Adriaanse, Product Manager at Atlas Copco Compressor Technique.

Dean cautions against the influx of cheaper, lesser-known air compressor brands into the market. “While the lower upfront costs of these machines are understandably appealing, their reliability and life cycle may be compromised. Additionally, access to service and parts could pose challenges. Ultimately, the higher cost of ownership makes them more expensive in the long run.”

Atlas Copco provides solutions for a wide range of needs, from complex, high-demand applications to the most basic air requirements. Dean points out that the premium tier air compressors incorporate cutting-edge technologies and functionality, which naturally come with a higher price tag. “However, we recognise that not all applications require high-end compressors with all the advanced features. Additionally, we understand that budget constraints may not allow for top-of-the-line options. However, whether operating premium or more economical machines, customers all demand a low total cost of ownership and a rapid return on their investment. Our mandate is therefore to supply air compressors that deliver best-in-class performance, efficiency and reliability, irrespective of their size, type or load requirement and whether they operate continuously or sporadically.”

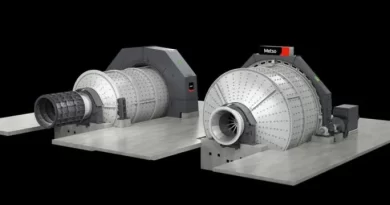

In a bid to offer a premium quality compressor to suit every air requirement and every budget, Atlas Copco Compressor Technique has segmented its air compressor portfolio into three quality tiers – the Professional

G and G VSD range, the Industrial GA and GA VSD series, and the Premium GA, GA FLX, GA VSDs and GA VSD+ range of compressors. “Each range caters to different segments of the market and offers excellent value for money,” explains Dean.

Atlas Copco’s economical G range (2.2 kW – 250 kW) is designed for customers with budget limitations and straightforward air requirements, offering reliable performance without unnecessary features. These powerful G range compressors provide best-in-class performance, reliability and efficiency that comparative low entry products simply cannot match. Their initial lower purchase outlay, combined with correctly sized machines and sound maintenance practices, will deliver a great return on investment for end-users. “We can also offer Variable Speed Drive (VSD) technology to customers within this segment whose air demand fluctuates,” adds Dean.

Atlas Copco’s indomitable GA and GA VSD (5.5kW – 500 kW) compressors are the workhorses in the Industrial segment. Built to perform even in the harshest environments, these tried, trusted and proven machines’ outstanding performance and high productivity keep production running efficiently and deliver a rapid return on investment.

Ranking on the top tier are the Atlas Copco premium GA FLX, GA VSDs and GA VSD+. Considered as the industry benchmark in quality, these flag ship machines offer added features, more functionality and more options. While VSD technology is included in the initial purchase price, the extreme efficiency of matching motor speed to air demand leads to unparalleled efficiency delivering significant savings, shorter payback periods and lowest possible cost of ownership.

Dean makes it very clear that irrespective of whether the customer’s compressed air requirement is on tier 1, 2 or 3, all Atlas Copco compressors are equal and offer the same superior quality, reliability and efficiency that is woven into the Atlas Copco brand. “Through ongoing R&D, smart design and cutting-edge technology, Atlas Copco continues to raise the performance, reliability and efficiency bars across all our air compressors, from economical to premium.”

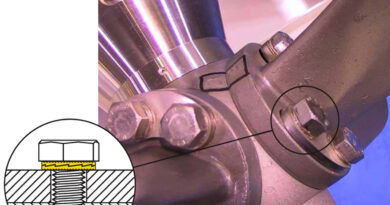

Effective maintenance practices and adherence to recommended service intervals, conducted by qualified technicians, are fundamental to machine performance, reliability, and efficiency. Dean outlines how service aligns with the three quality tiers. “The level of service will be determined by the relevant tier as well as the type of air compressor the customer selects. To ensure the integrity of the warranty, which is carried by all our machines, we always strongly recommend that customers adhere to the prescribed service intervals and use only genuine Atlas Copco parts.” “Our three-tier strategy propels our customer-driven narrative and gives us the ability to offer a budget- and application-appropriate compressed air solution that will optimise overall plant efficiency. Customers can rest assured in the knowledge that whichever compressor they decide to purchase, they will be able to count on Atlas Copco’s value proposition of quality,” concludes Dean.